DRY ICE BLASTING

Dry ice blasting is a safe and effective way to clean both machinery and surfaces. By propelling dry ice pellets at high speeds, we provide ice blasting that is less dense than sand blasting but just as effective.

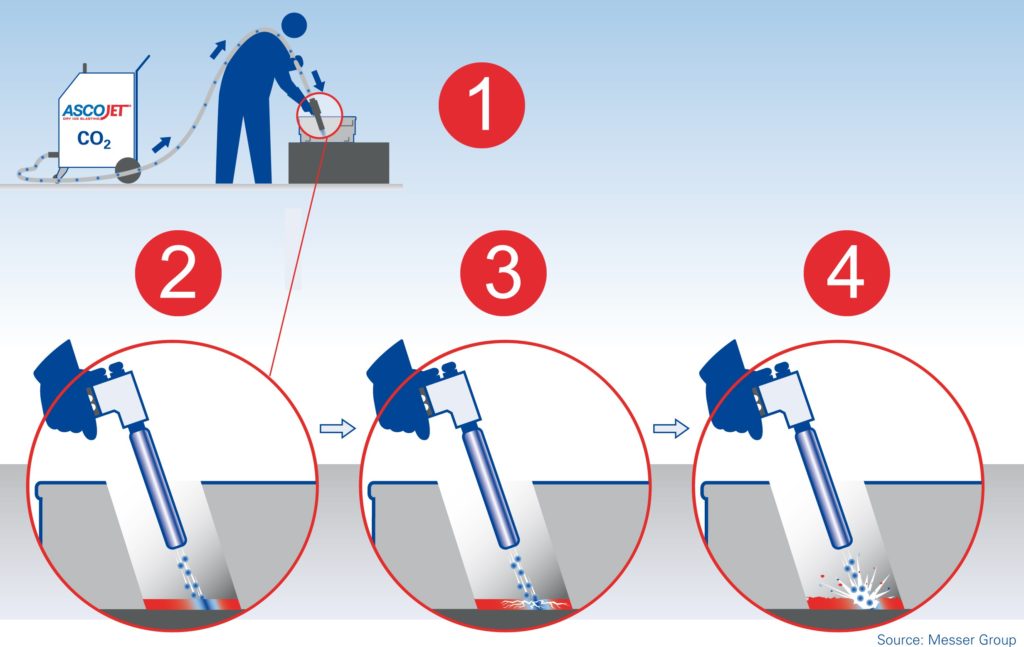

Gentle cleaning thank to dry ice blasting technology

- Cryogenic dry ice pellets are accelerated by means of compressed air

- Localised thermal shock causes soiling to contract

- Cracs form, and the material becomes brittle due to the cold

- Dry ice pellets hit the surface at a speed of 300 m/s and remove the loosened layer

Advantages over other cleaning methods

Gentle

Dry Ice Blasting is virtually non-abrasive. This means that in comparison to traditional blasting methods with sand or glass beads, the cleaned surfaces are not damaged or altered.

No dismantling

Dry Ice Blasting has the advantage that it can be applied directly to the moulds/plants without disassembling them.

Dry

Dry Ice Blasting is a dry cleaning method. Therefore even delicate parts like switch boards and other electric components can be cleaned gently.

No residual blasting media

Dry Ice Blasting leaves no residual blasting media behind because the dry ice pellets sublimate immediately after impact on the surface.

Ecologically friendly

Dry Ice Blasting is ecologically friendly. As mentioned, no residual blasting media has to be disposed of and no solvents or chemicals are needed.

Did You know?

ASCO Carbon Dioxide, a Messer subsidiary, is your partner for automatic dry ice production machines, CO2 production and recovery plants, dry ice blasting units, CO2 storage tanks, cylinder filling systems, vaporisers and other CO2 accessories. ASCO Carbon Dioxide offers a comprehensive range of technologies covering every aspect of CO2, with a particular focus on dry ice production and application.